The Power of Personalization in Custom Printing

In the ever-evolving world of custom apparel, the demand for unique, vibrant, and long-lasting designs has skyrocketed. Whether you’re a business owner, independent artist, or hobbyist, creating standout designs is crucial. That’s where the DTF (Direct-to-Film) print transfer process comes in—an innovation that has transformed how we think about custom printing.

At DTFSuperPrint.com, we specialize in providing cutting-edge DTF printing solutions that enable creators to bring their boldest ideas to life. In this in-depth guide, we’ll explore how to create unique prints using the DTF transfer method, from understanding the process to advanced design tips and troubleshooting techniques.

What is DTF Printing? A Quick Overview

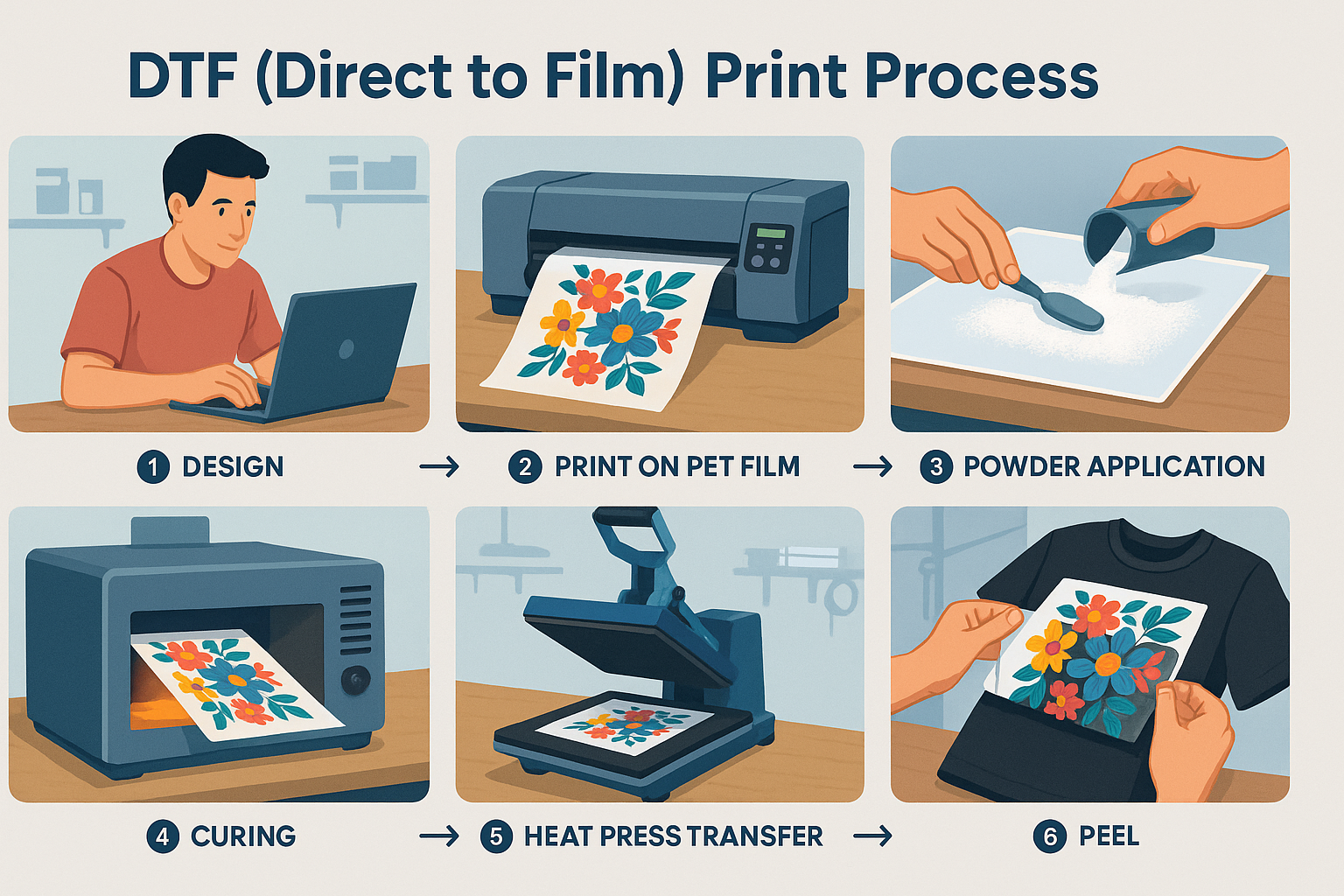

DTF (Direct to Film) printing is a method where designs are printed onto a special film and then transferred onto fabric using a heat press. This process differs from traditional screen printing or DTG (Direct to Garment) because it allows for:

- Higher durability

- More vibrant colors

- No need for pre-treatment

- Works on all fabric types (cotton, polyester, blends, etc.)

The basic DTF printing steps are:

- Design Creation

- Printing on PET Film

- Powder Application

- Curing (melting the powder)

- Heat Press Transfer onto garment

- Cold Peel

Let’s now dive into how you can leverage this technology to create one-of-a-kind prints.

Planning for Unique DTF Designs: Laying the Foundation

To create unique DTF prints, your design process should start with intentional planning.

a. Know Your Audience

Understanding your target customer helps you design graphics that resonate. For example:

- Streetwear enthusiasts prefer bold, urban, or graffiti-style prints.

- Christian apparel markets lean toward faith-based messages with stylized typography.

- Kidswear often features colorful, playful illustrations.

b. Choose a Design Style

Decide what aesthetic you want to achieve:

- Minimalist

- Retro/Vintage

- Cartoonish

- Abstract/Geometric

- Photorealistic

The DTF process supports photographic detail, so don’t be afraid to explore full-color imagery and complex shading.

Design Creation Tips for DTF Printing

Now that you know your audience and style, it’s time to get designing.

a. Use High-Resolution Graphics

Always create or source images at a minimum of 300 DPI. DTF can pick up even the tiniest design details, so your graphics should be crisp.

b. Use CMYK Color Mode

Since DTF printers print in CMYK, design your files in this color space for accurate color translation. This ensures what you see on screen is closer to what you get on the shirt.

c. Avoid Transparency and Gradients Without Testing

While DTF handles gradients well, some transitions might appear grainy. Test before going into full production. Avoid using soft drop shadows unless you’ve tested how they look after transfer.

d. Add White Underbase Where Needed

DTF printers print white ink as a base layer when required. Make sure to indicate white ink in your artwork if your software or RIP requires it.

e. Keep Cut Lines in Mind

If you’re offering gang sheets (multiple designs on one film), make sure there’s enough spacing between each print to allow for trimming.

Using Gang Sheets for Unique Product Offerings

One of the most effective ways to offer customized products is through DTF gang sheets.

What is a Gang Sheet?

A gang sheet allows multiple images or variations of a design to be printed on one film, saving time and money.

Gang Sheet Strategies:

- Include the same design in multiple sizes (for hoodies, baby onesies, hats)

- Combine related designs for bundle deals

- Personalize each name or message for customer-specific orders

At DTFSuperPrint.com, we support custom gang sheet uploads and bulk ordering, making it easy for small businesses and resellers to scale.

Choosing the Right Film and Ink

The quality of your final print also depends heavily on the materials used in the DTF process.

Best Film for Unique DTF Prints

- Cold Peel PET Film (most commonly used)

- Thickness: 75-100 microns

- Anti-static coating for cleaner prints

DTF Ink Considerations

- Use high-quality pigment inks

- Make sure white ink has good opacity and doesn’t crack after washing

- Compatible with Epson printheads or commercial DTF printers

At DTFSuperPrint.com, all our transfers are printed with premium-grade film and ink for long-lasting results.

Applying Adhesive Powder and Curing

The adhesive powder is what binds the ink to the fabric. To ensure perfect transfer:

- Shake powder evenly across the wet print

- Use a curing oven or heat press (hovering) to melt the adhesive

- Ensure the powder is melted but not burned—timing and temperature are key

For creators without access to high-end equipment, DTFSuperPrint.com offers ready-to-press DTF transfers—no powder or curing required!

Heat Pressing: Bringing the Print to Life

Here’s how to ensure a successful transfer:

Heat Press Settings (General Guide):

- Temperature: 300°F to 320°F (150°C to 160°C)

- Time: 10–15 seconds

- Pressure: Medium to Firm

Cold Peel vs. Hot Peel

- Most DTF transfers are cold peel, meaning you should wait until the transfer cools before peeling off the film.

- Always follow the peel instructions from your film supplier.

Pro Tip: After peeling, re-press with parchment paper for 5 seconds to lock in the ink and enhance durability.

Personalization and Niche Print Ideas

Looking for inspiration to create unique prints?

Trendy Ideas for 2025:

- Bible verses with florals (e.g., Ephesians 4:32 with soft colors)

- Funny retro summer graphics

- Matching family sets (vacation shirts, reunions)

- Personalized pet portraits

- Sports team fan shirts with player names

Offering seasonal, trending, or personalized designs can dramatically increase your product’s uniqueness and sales potential.

Troubleshooting Common DTF Print Issues

Even seasoned printers encounter issues. Here’s how to address the most common:

| Issue | Cause | Fix |

| Print not transferring fully | Low pressure or wrong temperature | Check your heat press settings |

| White ink cracking | Poor ink or fabric incompatibility | Use better-quality inks and ensure correct curing |

| Ink bleeding or smudging | Overheated powder | Adjust curing time or switch to quality film |

| Faded colors | Low-resolution artwork or ink quality | Design in 300 DPI, use vibrant CMYK palette |

DTFSuperPrint.com uses industry-tested supplies to eliminate many of these problems for our customers.

Why Choose DTFSuperPrint.com for Your Custom Printing Needs

At DTFSuperPrint.com, we make it easy to create truly unique, professional-quality DTF prints:

Our Advantages:

- Easy-to-use custom upload portal

- Bulk gang sheet printing support

- Pre-cured, ready-to-press transfers

- Fast shipping across the U.S.

- Competitive wholesale pricing

- Design and artwork assistance on request

Whether you’re a startup brand, boutique shop, or local artist, we provide the tools and support you need to thrive in the DTF space.

Final Thoughts: Standing Out with DTF Printing

Creating unique prints with the DTF transfer process isn’t just about aesthetics—it’s about tapping into what makes your brand, your customer base, and your designs different. By focusing on quality artwork, strategic printing techniques, and the right materials, you can produce stunning custom apparel that stands out in today’s crowded marketplace.

DTF printing is not just a trend—it’s the future of custom apparel. Ready to bring your unique designs to life?

👉 Start your custom DTF print journey at DTFSuperPrint.com