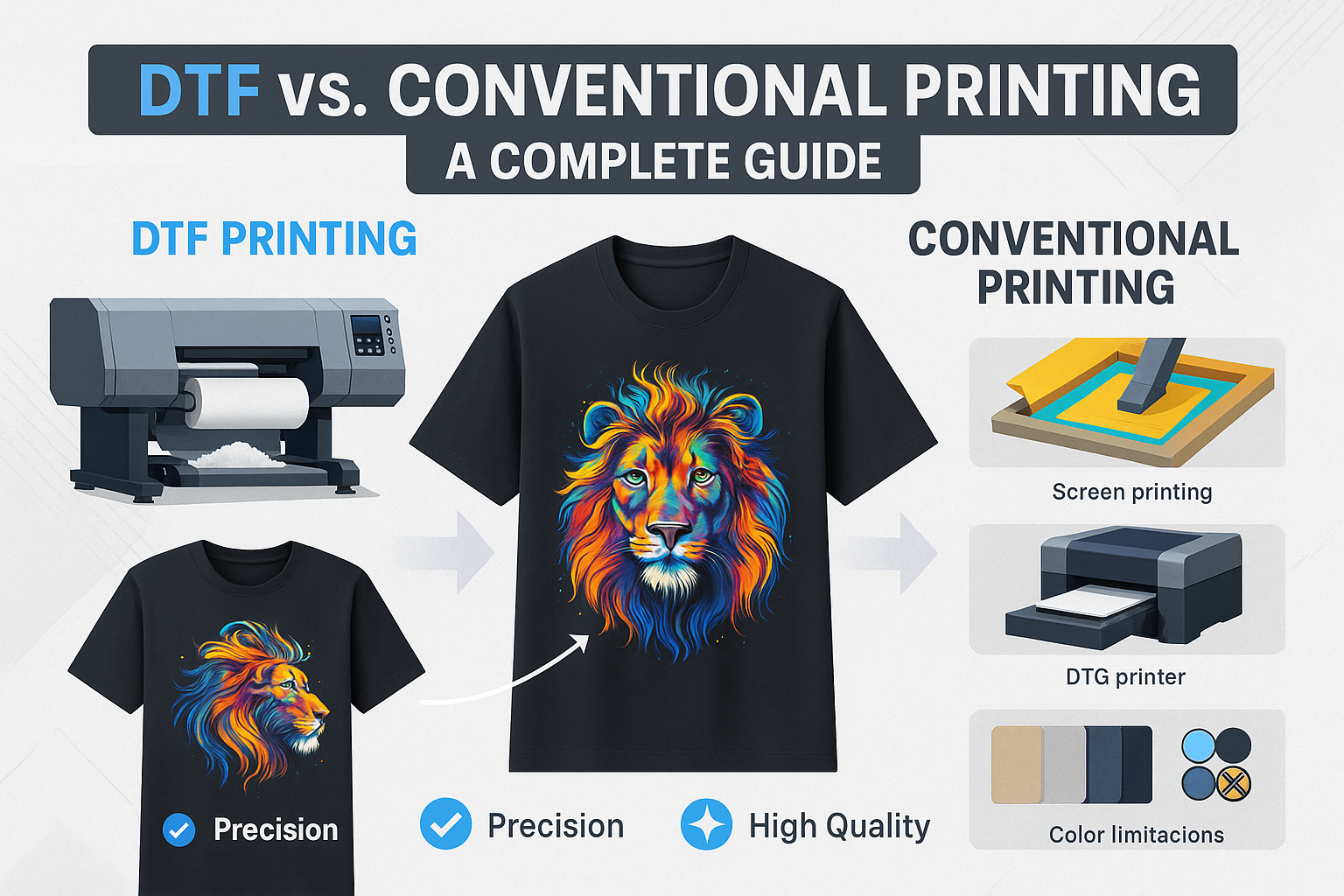

The printing industry has come a long way—from traditional screen printing techniques to modern digital technologies. One of the most talked-about innovations today is DTF (Direct-to-Film) printing. But how does it compare to conventional printing methods like screen printing, DTG (Direct-to-Garment), and sublimation?

If you’re a business owner, custom apparel designer, or print shop operator looking to choose the best method for your needs, this comprehensive guide will break down the key differences.

🖨️ What Is DTF Printing?

Direct-to-Film (DTF) printing is a cutting-edge technology where designs are digitally printed onto a special PET film using water-based pigment inks. After printing, a powder adhesive is applied and cured, and the design is then heat-pressed onto fabric.

Key Features of DTF:

- No need for pre-treatment

- Works on a wide range of fabrics

- Supports high-resolution, full-color printing

- Great for short runs and custom jobs

📊 DTF vs. Conventional Printing: Quick Comparison Chart

| Feature | DTF Printing | Screen Printing | DTG Printing | Sublimation Printing |

| Setup Time | Minimal | Time-consuming | Moderate | Minimal |

| Color Support | Full-color (CMYK+White) | Limited by screen count | Full-color (CMYK) | Full-color on light polyester |

| Fabric Compatibility | Cotton, poly, blends, denim | Mostly cotton or blends | Mostly cotton | Polyester only |

| Design Complexity | High (photo-quality) | Low–medium | High | High (on light backgrounds) |

| Print Durability | High | Very high | Medium | Very high |

| Best For | Custom, on-demand orders | Bulk orders | Cotton T-shirts | Polyester apparel & gifts |

| Minimum Order Quantity | None | Often required | None | None |

| Learning Curve | Easy to moderate | Steep | Moderate | Easy |

Color and Design Capabilities

- Supports vibrant, photo-quality images with gradients and fine details

- Includes white ink for dark garments

- No limitation on the number of colors

Screen Printing

- Each color requires a separate screen

- Ideal for bold, simple graphics

- Complex designs = higher setup cost and more labor

DTG Printing

- Great for full-color printing on light cotton fabrics

- Struggles with vibrant colors on dark garments unless pre-treated

Sublimation

- Amazing color and clarity, but only works on white or light polyester

👉 Winner: DTF for full-color versatility on all fabrics

Fabric Compatibility

DTF

- Works on cotton, polyester, blends, fleece, denim, canvas, nylon

- No pre-treatment required

Screen Printing

- Best for cotton and blends

- Requires different ink types for different fabrics

DTG

- Limited to 100% cotton for best results

- Polyester printing is possible but complex

Sublimation

- Works only on polyester and polymer-coated materials

👉 Winner: DTF for all-around versatility

Setup Time & Workflow

DTF

- Easy digital setup: Print → Powder → Heat press

- Fast turnaround for small or custom jobs

Screen Printing

- Labor-intensive setup: Burn screens, align layers, mix inks

- Better suited for bulk production

DTG

- Slower process on dark garments due to pre-treatment

- Not ideal for fast turnaround

Sublimation

- Quick and easy setup, but limited substrate options

👉 Winner: DTF for speed and flexibility

Cost Efficiency

- Lower setup costs

- Economical for small and custom runs

- Less labor-intensive

Screen Printing

- Cheaper per unit for large volumes

- Higher setup cost due to screens and labor

DTG

- High ink cost and maintenance

- Expensive equipment

Sublimation

- Low material cost, but limited to specific items

👉 Winner: DTF for small to medium orders

Durability and Washability

DTF

- High durability when cured properly

- Resistant to cracking, peeling, and fading

Screen Printing

- Industry gold standard for longevity

- Can last for years with proper care

DTG

- May fade or wash out over time, especially on dark garments

Sublimation

- Permanent dye becomes part of the fabric

- Excellent wash resistance

👉 Winner: Tie between DTF, Screen Printing, and Sublimation

Customization and Personalization

- Perfect for on-demand printing, individual names, or designs

- Easily adaptable to print small batches or one-offs

Screen Printing

- Not practical for customization

- Requires new screens for each variation

DTG

- Good for custom prints, but slower than DTF

Sublimation

- Works well for custom items if polyester-based

👉 Winner: DTF for personalized apparel and custom gifts

Equipment & Maintenance

DTF

- Requires printer, powder applicator (manual or auto), curing unit, and heat press

- Moderate maintenance (ink heads, powder residue)

Screen Printing

- Requires screens, press, ink, dryers, exposure units

- Takes up space and requires skilled labor

DTG

- Requires high-end printer and regular maintenance

- Sensitive to humidity and clogs

Sublimation

- Easy maintenance

- Minimal moving parts

👉 Winner: DTF for balanced cost and usability

🛍️ Use Case Scenarios

| Business Type | Recommended Method |

| T-shirt startups (print-on-demand) | ✅ DTF |

| Corporate bulk orders | Screen Printing |

| Polyester sportswear | Sublimation |

| Fashion brands (high-quality cotton) | DTG or DTF |

| Personalized gifts and names | ✅ DTF |

| Custom logo and branding merch | ✅ DTF |

DTF printing is revolutionizing the garment and custom product industry with:

- Unmatched fabric flexibility

- Fast and cost-effective production

- Stunning full-color prints

- Superior customization and small-batch capability

While conventional printing methods still hold value for specific applications (like screen printing for bulk and sublimation for polyester), DTF stands out as the most versatile solution for today’s dynamic, fast-paced, and personalized marketplace.

🛒 Get Started with DTF at DTFSuperprint.com

Looking to bring DTF printing to your business? At DTFSuperprint.com, we offer:

- High-quality ready-to-press DTF transfers

- Bulk DTF film, powder, and inks

- Easy-to-use gang sheet builder

- Fast shipping and friendly support

Start printing smarter, faster, and more profitably — with DTF Super Print as your go-to supplier.