Why Proper DTF Transfer Storage Matters

DTF (Direct to Film) printing is a game-changer in the custom apparel world. With its vibrant color accuracy, durability, and versatility, DTF transfers are ideal for small businesses, t-shirt brands, and print-on-demand services. However, no matter how high the print quality is, improper storage can ruin your DTF transfers before they even touch a garment.

This guide will walk you through everything you need to know about how to store DTF print transfers properly, from temperature and humidity to packaging, handling, and shelf life optimization.

Understanding DTF Transfers and Their Shelf Life

Before diving into storage best practices, let’s understand what DTF transfers are made of and why they require specific conditions.

What Are DTF Transfers?

A DTF transfer is a heat-applied design printed onto PET film using special DTF inks, adhesive powder, and a curing process. Once printed and cured, it’s ready to be applied to garments using a heat press.

Average Shelf Life of DTF Transfers

- Ideal shelf life: 6–12 months

- With proper storage: Up to 18 months

- With poor storage: Less than 3 months

Many factors can shorten the usable life of your transfers—humidity, dust, UV exposure, and improper packaging being the most common culprits.

Key Environmental Factors Affecting DTF Transfers

Let’s explore the main environmental conditions that can impact the shelf life and performance of your DTF transfers.

1. Temperature

Ideal storage temperature: 60–75°F (15–24°C)

Extreme heat can cause:

- Ink to fade or bleed

- Adhesive powder to harden or activate early

Extreme cold can lead to:

- Brittle film

- Adhesion failure during heat press

2. Humidity

Ideal humidity: 40%–60%

Too much moisture leads to:

- Sticky transfers

- Mold or mildew

- Powder clumping

Too little moisture causes:

- Static electricity

- Film curling

3. Light Exposure

Direct sunlight or strong indoor lighting can:

- Fade colors

- Degrade ink and adhesive

- Cause film warping

Pro Tip: Always store in a dark, enclosed space away from UV light.

4. Dust and Debris

Dust can settle on the adhesive or ink layer, causing print defects during pressing. A clean storage space is essential.

How to Package DTF Transfers for Long-Term Storage

Your packaging method is just as important as your storage conditions.

Best Packaging Materials

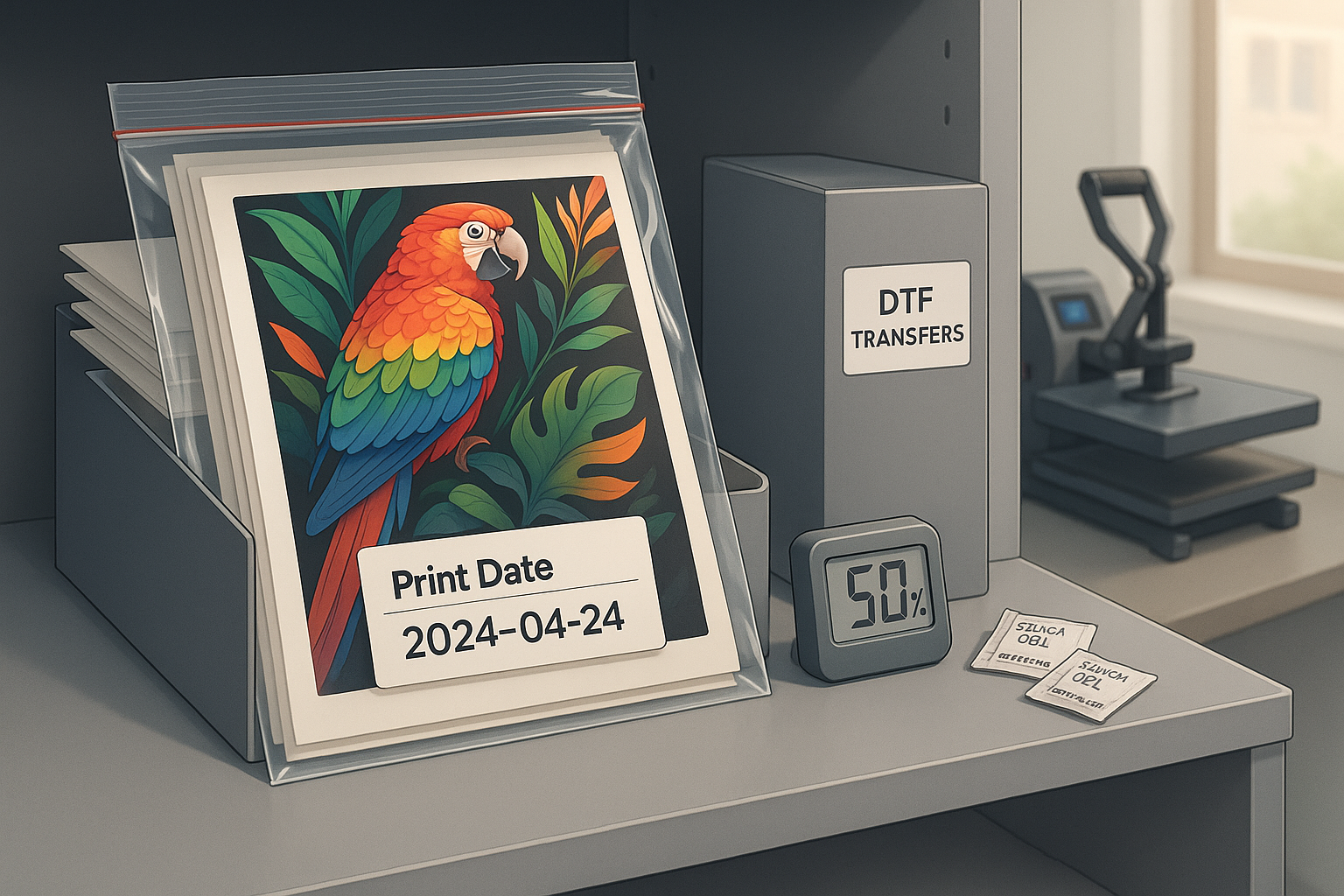

✅ Zip-lock or resealable poly bags

✅ Acid-free paper between transfers

✅ Rigid folders or boxes

✅ Silica gel packs for humidity control

Step-by-Step Packaging Guide

- Cool Down First: Allow transfers to cool completely before stacking or storing.

- Layer Wisely: Place acid-free or parchment paper between each sheet to avoid sticking.

- Seal It Tight: Use resealable bags or vacuum-sealed containers.

- Label Everything: Note the print date, design name, and batch number.

Choosing the Right Storage Location

Where you store your DTF prints is just as important as how you store them.

Ideal Locations

- Climate-controlled rooms or closets

- Clean dry drawers or filing cabinets

- Dark boxes placed on shelves (not floor level)

Locations to Avoid

🚫 Garages or sheds

🚫 Attics or basements

🚫 Near heaters, windows, or humidifiers

🚫 Direct contact with sunlight or air vents

Bonus Tip: Use airtight containers with desiccant packs to prevent moisture buildup, especially in humid climates.

How to Handle DTF Transfers Without Damaging Them

Storage isn’t just about the environment—it’s about how you handle the transfers too.

Handling Tips

- Clean hands or gloves only: Oils from your skin can transfer to the print

- Avoid bending or folding: PET film can crack or crease

- Flat stacking only: Never roll unless absolutely necessary

Organizing for Quick Access

Set up a labeled filing system using:

- Transparent file folders

- Vertical shelf organizers

- Alphabetical or color-coded systems

This ensures fast, damage-free access to your prints when you’re ready to press.

Special Considerations for Bulk DTF Print Storage

If you run a DTF print shop or stock hundreds of transfers, these bulk storage strategies will help.

Best Practices for Bulk DTF Storage

- Group transfers by size, design type, or customer

- Use archival-quality boxes or plastic bins

- Include inventory sheets inside each container

- Keep rotating stock – “first in, first out” method

Use of Vertical Storage Cabinets

- Helps save space

- Prevents crushing of bottom prints

- Easy to add labeling systems

Common DTF Storage Mistakes to Avoid

Avoid these mistakes to keep your prints in perfect condition:

| Mistake | Why It’s Harmful |

| Storing in open air | Dust & humidity exposure |

| Leaving in hot press room | Heat degrades ink/adhesive |

| Stacking without separators | Causes sticking, damage |

| Using cardboard boxes without lining | Can cause moisture transfer |

| Storing on the floor | Attracts moisture and pests |

How to Test Old or Aged DTF Transfers

If you’ve had transfers in storage for months, test before applying to valuable garments.

Testing Tips

- Press a small scrap fabric with the transfer

- Check for:

- Ink vibrancy

- Adhesion strength

- Film warping

If colors are dull or adhesive doesn’t bond well, the transfer may have expired.

Pro Tips from the Experts at DTFSuperPrint.com

Here are a few insider tips from our team at DTFSuperPrint.com to keep your transfers in tip-top shape:

✅ Tip 1: Store by Print Date

Use a label system with print date so you always use the oldest ones first.

✅ Tip 2: Avoid Stacking Hot Prints

Let all transfers cool before stacking to avoid ink transfer or sticking.

✅ Tip 3: Use Storage Bins with Compartments

Separate designs by type or customer orders for speed and accuracy.

✅ Tip 4: Monitor Climate with a Hygrometer

Keep a cheap digital hygrometer inside your storage space to ensure ideal humidity.

Storing Pressed vs. Unpressed Transfers

Sometimes, you may want to store leftover transfers for future use or even store already-pressed designs.

Storing Unused Transfers

Follow all tips above.

Storing Garments With DTF Transfers

- Fold gently to avoid cracking

- Use tissue paper between folds

- Keep in cool, dry places

Never vacuum-seal a garment with a DTF transfer—it may wrinkle or damage the print over time.

Protect Your Investment with Smart Storage

DTF transfers are an investment in your business, whether you print in-house or purchase ready-to-press designs. By following these DTF transfer storage tips, you’ll ensure that every design stays sharp, colorful, and ready to wow your customers—whether it’s used tomorrow or a year from now.

Want Perfect Transfers Every Time?

At DTFSuperPrint.com, we not only deliver vibrant, high-quality DTF prints but also guide you every step of the way. From care instructions to business growth advice, we’re your trusted DTF partner.

Quick Recap: Storing DTF Transfers Checklist

✅ Store in a cool, dry, dark place

✅ Keep humidity between 40%–60%

✅ Use acid-free separators and resealable bags

✅ Avoid sunlight and heat sources

✅ Always handle with clean hands

✅ Label and rotate stock regularly

✅ Use testing for long-stored designs

Want to try DTF transfers that are built to last?

👉 Browse our Ready-to-Press DTF Designs today or learn more on our blog.

📦 Have questions about bulk storage or business printing?

Contact our team anytime — we’re here to help!